In ceramic making, “firing temperature” is one of the key variables influencing the final performance and characteristics of ceramics. Whether pottery, porcelain, functional tableware, or art ceramics, the firing temperature setting for each ceramic is influenced by its technical material composition, purpose of use, and aesthetic purpose. So, how exactly do we define temperature ranges during ceramic firing? What is high firing and low firing? And lastly, what do you term “the ordeal temperature” (the critical test temperature)? This article will answer your questions.

Introduction to Ceramic Firing Temperatures

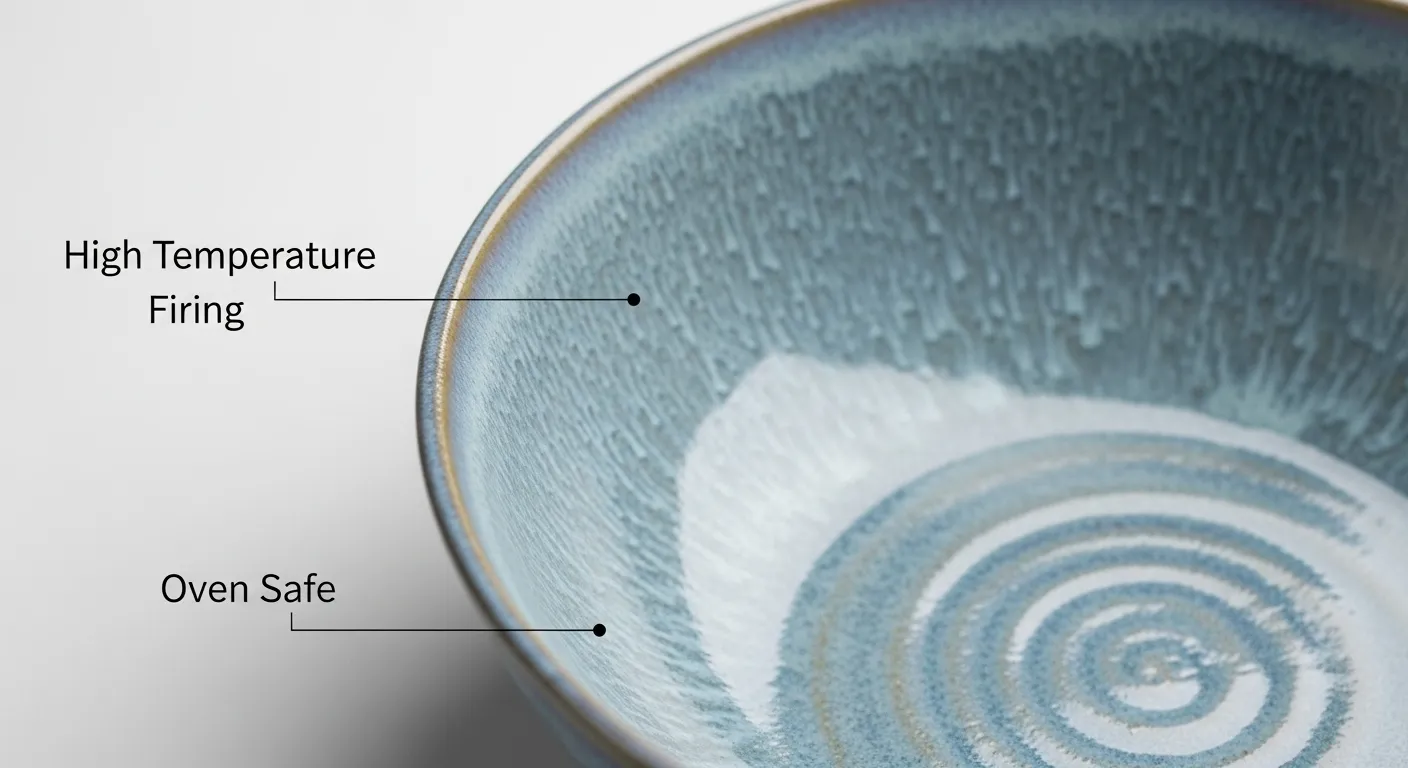

Firing ceramics is more than just a heat source- it is a transformation process in physical and chemical form. Ultimately at high firing temperatures, the ceramic body undergoes stages of dehydration, sintering, densification, and vitrification, creating a ceramic product that has high strength and durability.

Common firing temperature ranges:

- Low-range firing: approximately 700°C–1,050°C

- Mid-range firing: approximately 1,050°C–1,200°C

- High-range firing: approximately 1,200°C–1,400°C

Differences between high- and low-temperature firing

- Different firing results

High-temperature firing:

- Produces denser and stronger ceramics;

- Suitable for porcelain products such as household porcelain, bone china, and high-end craft porcelain;

- Often accompanied by vitrification of the glaze, resulting in a smooth, wear-resistant, and impermeable glaze.

Low-range firing:

- The finished product is porous and has a higher water absorption rate;

- It is more suitable for flower pots, stoneware decorations, and artistic pottery;

- Produces richer colors and more flexible glaze variations, making it suitable for handmade artistic pottery.

- Variation in Energy Usage and Costs

- High-fire ceramics require greater kiln tolerances and use a larger amount of energy.

- Low-fire ceramics are more energy-efficient and environmentally sustainable, and they typically use much less energy. On the other hand, low-fire ceramics would work well for product lines with specialized process specifications and limited budgets.

- Variation in Glaze Performance

- High-fire glazes have a higher melting point, resulting in soft and natural colors.

- Low-fire glazes provide bright, colorful, and varying decorative appearances, and they would be an appropriate choice for artistic ceramic pieces.

In closing, high-fire isn’t always the best choice; the firing method should be chosen to suit the product type and purpose.

What is “ordeal temperature”?

Ordeal temperature refers to the minimum temperature required of ceramics during the firing process, below which there are substantial changes (crystal reorganizations) in the ceramic body, the melting point, and/or the beginning of the vitrification process. If this temperature is not achieved the ceramics will not strengthen structurally and the finished product may succumb to complications such as powdering, cracking, etc., and have higher water absorption rates.

For example:

- The ordeal temperature of porcelain is typically around 1,250°C.

- Stoneware ceramics are around 1,100°C;

- Alumina ceramics can reach temperatures exceeding 1,600°C.

Understanding the significance of ordeal temperature helps precisely control the firing process, ensuring both durable and beautiful ceramic products.

Related Products

Practical Considerations on Ceramic Firing Processes

In actual ceramic manufacturing, controlling firing temperature is not a fixed process; rather, it is a flexible process based on the formulation, intended use, product thickness, and glaze type. Especially in Chaozhou, a region with a well-developed ceramic industry, manufacturers not only pursue precise temperature control but also emphasize the combination of thermal engineering experience and atmosphere control—this is the secret to achieving both stable mass production and unique ceramic products.

Chaozhou Ceramic Manufacturers Association

The Chaozhou Ceramic Manufacturers Association is the hub linking together a collection of certified, high-quality ceramic manufacturers from Chaozhou. Each of these manufacturers has a wealth of knowledge about firing methods, is adept at controlling a range of temperature curves, and can handle anything from low-temperature household ceramics to high-temperature artistic ceramics and architectural ceramics.

Whether you are looking for functional ceramics that will be suitable for the export market, including custom glazed art ceramics of a premium quality, you can find manufacturers to meet your specifications. We encourage visiting the association’s recommended page for manufacturers:

👉 Click to view a list of high-quality Chaozhou ceramic manufacturers.

On this platform, you can:

- Browse each manufacturer’s areas of expertise.

- Quickly filter suppliers for high- or low-temperature firing;

- Get one-on-one product customization advice.

Conclusion

Firing temperature is a core variable in ceramic manufacturing. The choice between high and low temperatures influences product positioning, style, and performance. Understanding this critical threshold, “ordeal temperature,” also helps enhance product stability and design freedom. The Chaozhou Ceramic Manufacturers Association is committed to exploring the beauty of firing techniques with global buyers and recommending trusted ceramic manufacturing partners.

For more information on ceramics or to find custom ceramic manufacturers, please continue to follow our blog or visit the Chaozhou Ceramic Manufacturers Association’s official website.